Table top dispensing machine, high speed inline dispensing system and various valves provide a variety of dispensing solutions.

X,Y,Z axis servo + ball screw driving system.

High precison valves (option).

Max 350*300mm PCB size capable

CCD Visual system.

Industrial PC and windows operation system, full English interface.

DetailsX,Y,Z axis servo + ball screw driving system.

High precison valves (option).

Max 350*300mm PCB size capable

CCD Visual system.

Industrial PC and windows operation system, full English interface.

X/Y axis controlled by Panasonic servo motor & ballscrew, max speed 1500mm/s

Max W400*D430mm PCB capable

Repeatable accuracy: +/-0.025mm

Nozzle temperature control system

Nozzle vacuum cleaning

Liquid level in tube detecting system

X/Y/Z axis auto correction platform

Visual system

Not including valve

DetailsX/Y axis controlled by Panasonic servo motor & ballscrew, max speed 1500mm/s

Max W400*D430mm PCB capable

Repeatable accuracy: +/-0.025mm

Nozzle temperature control system

Nozzle vacuum cleaning

Liquid level in tube detecting system

X/Y/Z axis auto correction platform

Visual system

Not including valve

Standard configuration:

X/Y axis controlled by servo motor& ballscrew, max speed 1000mm/s

Max W580*D580mm PCB capable

Repeatable accuracy: +/-0.05mm

Nozzle temperature control system

Nozzle vacuum cleaning

Liquid level in tube detecting system

X/Y/Z axis auto correction platform

Visual system

not including valve

DetailsStandard configuration:

X/Y axis controlled by servo motor& ballscrew, max speed 1000mm/s

Max W580*D580mm PCB capable

Repeatable accuracy: +/-0.05mm

Nozzle temperature control system

Nozzle vacuum cleaning

Liquid level in tube detecting system

X/Y/Z axis auto correction platform

Visual system

not including valve

Standard configuration:

Installed valve quantity: 1 set

X/Y axis controlled by linear motor,max speed 2000mm/s.

Max W380*D430mm PCB capable(single valve )

W340*D430mm (double valve )

Repeatable accuracy: +/-0.02mm

Nozzle temperature control system

Nozzle vacuum cleaning/paper cleaning system.

Liquid level in tube detecting system.

X/Y/Z axis auto correction platform.

Visual system

not including valve

DetailsStandard configuration:

Installed valve quantity: 1 set

X/Y axis controlled by linear motor,max speed 2000mm/s.

Max W380*D430mm PCB capable(single valve )

W340*D430mm (double valve )

Repeatable accuracy: +/-0.02mm

Nozzle temperature control system

Nozzle vacuum cleaning/paper cleaning system.

Liquid level in tube detecting system.

X/Y/Z axis auto correction platform.

Visual system

not including valve

X/Y/Z 3 axis step motor control.

Hand-held teach pendant for programming

Max 300*300mm PCB width.

Built in dispensing controller with independant air regulator.

Virous dispensing valve meet different requirement.

Customized glue feeding system is optional.

Double dispensing head is optional.

DetailsX/Y/Z 3 axis step motor control.

Hand-held teach pendant for programming

Max 300*300mm PCB width.

Built in dispensing controller with independant air regulator.

Virous dispensing valve meet different requirement.

Customized glue feeding system is optional.

Double dispensing head is optional.

X/Y1/Y2/Z 4 axis step motor control.

Hand-held teach pendant for programming.

Max 300*300mm PCB width capable * 2pcs.

Built in dispensing controller with independant air regulator.

Virous dispensing valve meet different requirement.

Customized glue feeding system is optional.

Double dispensing head is optional.

DetailsX/Y1/Y2/Z 4 axis step motor control.

Hand-held teach pendant for programming.

Max 300*300mm PCB width capable * 2pcs.

Built in dispensing controller with independant air regulator.

Virous dispensing valve meet different requirement.

Customized glue feeding system is optional.

Double dispensing head is optional.

X/Y axis adopt high quality close-loop step motor and it's driving system, ensure stable and precise run of motion system.

Y Platform is equipped with 2 rotatable axis which can rotate 360 degree, realize dispensing glue on 4 side of the product.

Double head Dispensing system.

Handheld teach pendant with english interface, easy to operate.

Powerful software realize point, line, arc, circle etc dispensing process. Dispensing speed, time, delay time etc parameter can be set on software.

X/Y axis travel: 400mm/400mm

DetailsX/Y axis adopt high quality close-loop step motor and it's driving system, ensure stable and precise run of motion system.

Y Platform is equipped with 2 rotatable axis which can rotate 360 degree, realize dispensing glue on 4 side of the product.

Double head Dispensing system.

Handheld teach pendant with english interface, easy to operate.

Powerful software realize point, line, arc, circle etc dispensing process. Dispensing speed, time, delay time etc parameter can be set on software.

X/Y axis travel: 400mm/400mm

The BD-400YR is an automated desktop type dispensing Robot with tiltable and rotary platform, which can realize no dead angle glue dispenisng compared with traditional 3 axis dispensing robot.

DetailsThe BD-400YR is an automated desktop type dispensing Robot with tiltable and rotary platform, which can realize no dead angle glue dispenisng compared with traditional 3 axis dispensing robot.

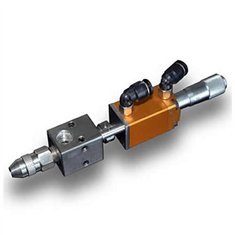

Plunger structure, flow rate can be ajusted precisely by micrometer, small size and corrosion -resistant, it is suitable for UV glue, paint, oil etc. low viscosity, and good fluidity glue.

DetailsPlunger structure, flow rate can be ajusted precisely by micrometer, small size and corrosion -resistant, it is suitable for UV glue, paint, oil etc. low viscosity, and good fluidity glue.