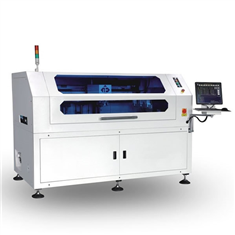

Fast, accurate printing of solder paste for SMT processing, plus ultrasonic cleaning for stencils.

Arch bridge type suspending direct-connected scraper, programmable printing head.

Double sliders ensures the printing head moving accuracy and stability when scraper is running back and forth.

Programmable motor controls conveying speed and conveys PCB in the precise position.

The cleaning unit is separated from CCD camera, which can minimize the load of motor, improve the positioning precision and speed.

Automatic conveyor width adjustment.

Auto stencil cleaning(Dry/Wet/Vacuum).

Automatic 2D paste inspection.

DetailsArch bridge type suspending direct-connected scraper, programmable printing head.

Double sliders ensures the printing head moving accuracy and stability when scraper is running back and forth.

Programmable motor controls conveying speed and conveys PCB in the precise position.

The cleaning unit is separated from CCD camera, which can minimize the load of motor, improve the positioning precision and speed.

Automatic conveyor width adjustment.

Auto stencil cleaning(Dry/Wet/Vacuum).

Automatic 2D paste inspection.

● Arch bridge type suspending direct-connected scraper, programmable printing head.

● Double sliders ensures the printing head moving accuracy and stability when scraper is running back and forth.

● Programmable motor controls conveying speed and conveys PCB in the precise position

● The cleaning unit is separated from CCD camera, which can minimize the load of motor, improve the positioning precision and speed.

● Automatic conveyor width adjustment.

● Auto stencil cleaning(Dry/Wet/Vacuum).

● Automatic 2D paste inspection.

Details● Arch bridge type suspending direct-connected scraper, programmable printing head.

● Double sliders ensures the printing head moving accuracy and stability when scraper is running back and forth.

● Programmable motor controls conveying speed and conveys PCB in the precise position

● The cleaning unit is separated from CCD camera, which can minimize the load of motor, improve the positioning precision and speed.

● Automatic conveyor width adjustment.

● Auto stencil cleaning(Dry/Wet/Vacuum).

● Automatic 2D paste inspection.

Application: Solder past, red glue on SMT Stencil, squeegee, etc.

Stainless steel machine body and cleaning cabinet

Full Pneumatic Control without fire risk

3 stage precision filtering system

high quality parts with long service life.

DetailsApplication: Solder past, red glue on SMT Stencil, squeegee, etc.

Stainless steel machine body and cleaning cabinet

Full Pneumatic Control without fire risk

3 stage precision filtering system

high quality parts with long service life.

500g/1000g Up two container can be loaded

Include balance block

LED Digital Display

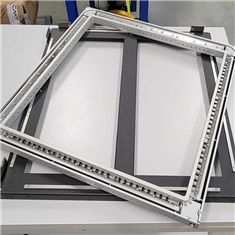

System features

Black anodized Aluminum extrusion with precision engineered tension & release

Tension method: mechanical 4-way multi_x005f point uniform springs tensioning with no foil distortion

Release Method: 4-Sided pneumatic system through silicon expansion bladder

Foil positioning method: Elongated slots around the four edges of the stencil foil

Compressed air: 4-5 bar

DetailsSystem features

Black anodized Aluminum extrusion with precision engineered tension & release

Tension method: mechanical 4-way multi_x005f point uniform springs tensioning with no foil distortion

Release Method: 4-Sided pneumatic system through silicon expansion bladder

Foil positioning method: Elongated slots around the four edges of the stencil foil

Compressed air: 4-5 bar

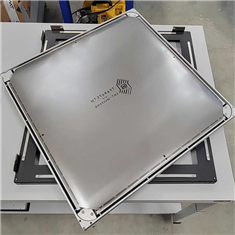

System features

Black anodized Aluminum extrusion with precision engineered tension & release

Tension method: mechanical 4-way multi_x005f_x0002_point uniform springs tensioning with no foil distortion

Release Method: 4-Sided pneumatic system through silicon expansion bladder

Foil positioning method: Elongated slots around the four edges of the stencil foil

Compressed air: 4-5 bar

DetailsSystem features

Black anodized Aluminum extrusion with precision engineered tension & release

Tension method: mechanical 4-way multi_x005f_x0002_point uniform springs tensioning with no foil distortion

Release Method: 4-Sided pneumatic system through silicon expansion bladder

Foil positioning method: Elongated slots around the four edges of the stencil foil

Compressed air: 4-5 bar